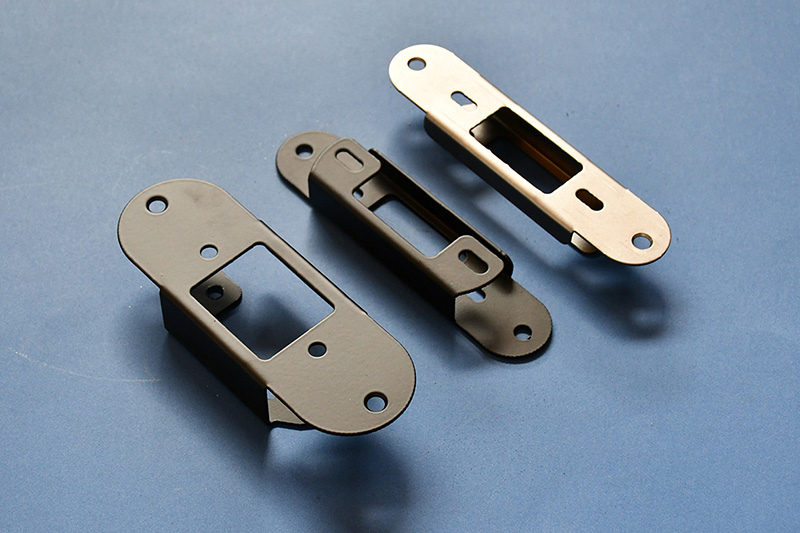

SHEET METAL STAMPING

We produce in series sheet metal stamped components and objects.

Our stamping lines have a maximum capacity of 320 tons and a maximum working table of 2130 x 1370 mm.

We make the ordinary and extraordinary maintenance of the dies.

We also make the assembly of the metal stamped components inside assemblies with electrical and electromechanical elements, delivering the complete product to the customer.

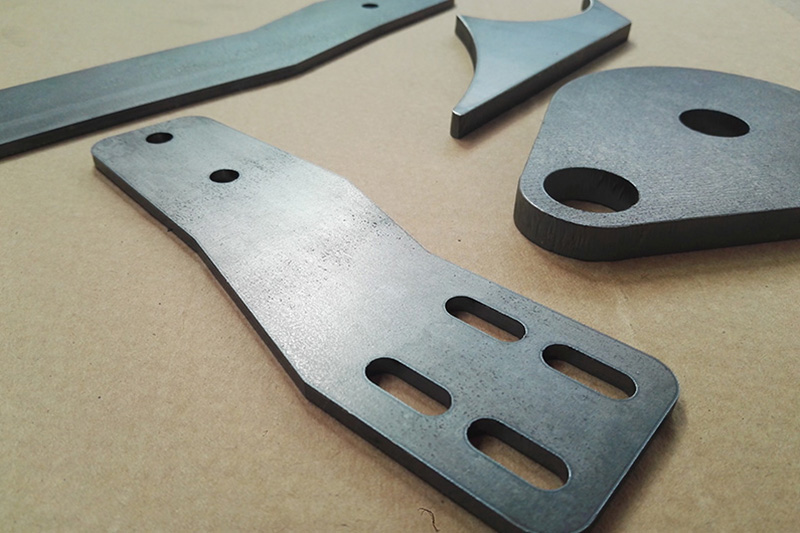

2D Laser Cutting

We have TRUMPF CO2 laser cutting systems to process stainless steel, steel and aluminum sheet metal, with automatic sheet metal loading system. Our laser cutting allows us to achieve perfect quality, even with the thinnest contours, getting edges without any burrs.

With the laser cutting, we make contours of any geometry, assisting the customer in the design of the workpiece.

We make unique pieces, small and large production lots.

PUNCHING

We have TRUMPF automatic punching systems for flexible machining of a wide range of sheet metal products. In addition to punching, our machines offer the possibility of making deformations or threads.

We guarantee a flexible production with tools suitable for various applications, for example for making brackets, rectangular or round cups, roller folding, ribs, threads, countersinks and other types of sheet metal deformation.

We make unique pieces, small and large production lots

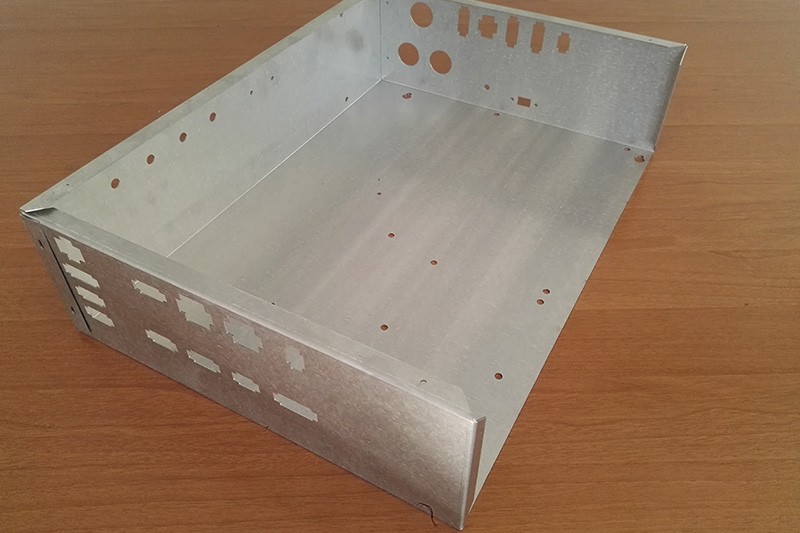

BENDING

We have TRUMPF CNC bending systems. The flexibility of our systems allows us to bend profiles of varying length or thickness and objects of high complexity. The versatility of our systems allows the production of small lots with high standards of accuracy and our wide range of tools allows us to obtain different bending radius and seams.

We produce components of varying size and thickness, on which we assemble electrical and or electronic components of different types

PUNCHING

We have TRUMPF automatic punching systems for flexible machining of a wide range of sheet metal products. In addition to punching, our machines offer the possibility of making deformations or threads.

We guarantee a flexible production with tools suitable for various applications, for example for making brackets, rectangular or round cups, roller folding, ribs, threads, countersinks and other types of sheet metal deformation.

We make unique pieces, small and large production lots

BENDING

We have TRUMPF CNC bending systems. The flexibility of our systems allows us to bend profiles of varying length or thickness and objects of high complexity. The versatility of our systems allows the production of small lots with high standards of accuracy and our wide range of tools allows us to obtain different bending radius and seams.

We produce components of varying size and thickness, on which we assemble electrical and or electronic components of different types

BARS AND PROFILES

We perform the machining of bars and profiles to manufacture furniture structures and carpentries made of bars and bent tube.

Welding and finishing steel and stainless steel

We specialized in TIG and MIG welding of all kinds of steels and we perform the MIG welding of aluminum materials.

We make sheet metal compositions and welded structures for furnishing. We perform the finishing, smoothing and polishing of metals, making products of aesthetic value

TURNING PROCESS

We have CNC turning systems with on-board CAM.

We make turning operations for third parties and furnishing components.

We program the machines using the CAM Esprit software, guaranteeing flexibility and quality of the product.

We perform assembly of the turned components into our products.

MILLING PROCESS

We have CNC milling machines and we perform the machine programming using the CAM Esprit software.

We perform milling operations with maximum flexibility.

MEASUREMENT

With our Mitutoyo Crysta Plus M 7106 3D coordinate measuring machine we certify the dimensional quality of our products.

We offer Quality Check services by issuing documentation that certifies the measurement of the product.